Skid Steer Loader Information

A skid loader, skid-steer loader, SSL, or skidsteer is a small, rigid-frame, engine-powered machine with lift arms that may attach to various buckets and other labor-saving tools or accessories.

The front and rear wheels on each side of skid-steer loaders are mechanically linked to turn at the same speed, and the left-side drive wheels have autonomous control over the right-side drive wheels. These vehicles are commonly four-wheeled or tracked. This is accomplished by using two unique and independent transmissions, one for the left-side wheels and one for the right-side wheels. The initial versions of skid steer loaders had both forward and backward clutch drives. Nearly all modern skid steers were constructed with two distinct hydrostatic transmissions beginning in the middle of the 1970s (one for the left side and one for the right side).

Without a separate steering mechanism, the wheels are often fixed on the machine's body in a straight alignment. Due to differential steering, in which the left and right wheel pairs are powered at different rates, the machine turns by sliding or dragging its fixed-orientation wheels across the ground. Skid-steer loaders can make zero-radius turns by pushing one set of wheels forward while moving the other set of wheels backward. Due to their "zero-turn" feature, these machines are very manoeuvrable and useful for applications that demand for a tiny, strong, and agile loader or tool carrier in confined places (the machine can turn around within its own length).

Due to the machine's very rigid structure and strong wheel bearings, the torsional forces generated by this dragging motion cannot damage it. Due to their high ground friction, skid steers can damage supple or sensitive road surfaces similarly to tracked vehicles. They can be modified to have less ground friction by using specially made wheels, such the Mecanum wheel.

The term "compact track loader" refers to skid-steer loaders that have tracks rather than wheels.

Skid steer loaders, both wheel and track models, function best when they are unbalanced, with either the front or the back wheels being heavily loaded. When the bucket is empty, skid steer loaders are all heavier towards the back, which causes the rear wheels to pivot as the front wheels move. The weight distribution shifts when a bucket is fully loaded, and the front wheels begin to weigh significantly more than the back wheels. When making a zero-turn while loaded, the front wheels revolve and the back wheels slide.

An imbalanced machine requires less power to turn and goes through its tyres more gradually. Skilled operators always keep the front or back of the machine more fully loaded. Both sets of wheels resist pivoting or sliding when the weight is evenly distributed between the front and rear axles and is at (or nearly at) 50/50, and the machine starts to "buck" as a result of the high friction. In this situation, tyre wear significantly increases.

In contrast to a conventional front loader, these machines feature raise arms alongside the driver with pivot points behind the driver's shoulders. Since the operator was so close to moving booms in the early skid loaders, they were less safe than conventional front loaders, especially since there was no rollover protection structure. Modern skid loaders include additional safety measures and open or fully covered cabs. Similar to other front loaders, they may move materials from one location to another, transport materials in the bucket, load materials into trucks or trailers, and perform a variety of digging and grading jobs.

History - Skid Steer Loaders

In 1957, brothers Cyril and Louis Keller of Rothsay, Minnesota, invented the first front-end loader with three wheels. The loader was built by the Keller family to help farmer Eddie Velo automate the removal of turkey excrement from his barn. Its name refers to the fact that the compact and lightweight equipment could spin around within its own length while doing tasks that a typical front-end loader would perform.

The Keller family was hired by the Melroe brothers of Gwinner, North Dakota's Melroe Manufacturing Company to continue perfecting their invention in 1958 after they purchased the patent rights to the Keller loader. By the end of 1958, the M-200 Melroe self-propelled loader was the fruit of this collaboration. It had two independent front-drive wheels, a rear caster wheel, a 12.9 horsepower (9.6 kW) engine, and a 750-pound (340 kg) lift capability. Two years after the caster wheel was switched out for a rear axle, the first four-wheel, real skid-steer loader, the M-400, was introduced. A 15.5 horsepower (11.6 kW) engine powers the M-440, which has a rated operating weight of 1,100 pounds (500 kg). Skid-steer development continued with the M600 loader into the middle of the 1960s. Melroe registered the recognisable Bobcat brand in 1962.

Cyril and Louis Keller, two brothers from Rothsay, Minnesota, created the first front-end loader with three wheels in 1957. The Keller family constructed the loader to aid farmer Eddie Velo in automating the collection of poultry waste from his barn. Its name alludes to the equipment's ability to rotate around within its own length while carrying out activities that a standard front-end loader would carry out.

In 1958, after acquiring the Keller loader's patent rights, the Melroe brothers of Gwinner, North Dakota's Melroe Manufacturing Company engaged the Keller family to continue perfecting their innovation. The M-200 Melroe self-propelled loader was the result of this collaboration by the end of 1958. It possessed a 12.9 horsepower (9.6 kW) engine, two independent front-drive wheels, a rear caster wheel, and a lifting capacity of 750 pounds (340 kg). The first four-wheel, true skid-steer loader, the M-400, was released two years after the caster wheel was replaced with a rear axle. The M-440's 15.5 horsepower (11.6 kW) engine pushes its 1,100 pound rated working weight (500 kg). With the M600 loader, skid-steer development lasted through the middle of the 1960s. The recognisable Bobcat brand was trademarked by Melroe in 1962.

Skid Steer Loader Applications

By digging a hole from the inside, a skid-steer loader can occasionally replace a large excavator. This is particularly true when putting swimming pools in backyards that are too tiny to accommodate a large digger. The target excavation's edge is initially reached by the skid loader by building a ramp there. After that, it uses the ramp to carry material out of the hole. The ramp is lengthened and made steeper by the skid loader as the excavation depth increases. This method can also be used if there isn't enough overhead clearance for a large excavator boom but you wish to construct a basement beneath an existing house. There are numerous companies who produce backhoe attachments for skid-steers. These are more effective than the method mentioned above for excavating in a small area and can be utilised in the same circumstances.

Other applications include using pallet forks or buckets to transport raw materials around a construction site. Tough terrain forklifts have very poor manoeuvrability while rough terrain forklifts are smaller and have great movement but poor traction. Skid steer loaders are extremely manoeuvrable and have good traction, while typically having lower lift capacity than forklifts.

Skid steer loaders are excellent for clearing snow in confined parking areas when larger snow ploughs struggle to manoeuvre past existing cars, lamp posts, and curbs. Skid steers have the ability to remove snow rather than just plough it and push it onto a mound.

Applications For Small Frame Loaders

If you operate in trenching, levelling, post hole digging, small demolition, material transfer, building, and site development, you should look into compact skid steers. Due to their small size and high esteem for mobility, they are ideal for any occupation where space may be at a premium. Landscapers can avoid the most fragile terrain and damage an established grass the least by using their light weight.

Applications for Medium Frame Loaders

For any project requiring precision movement, skid steers with a medium frame work best. At any construction or material management site, they are good at clearing debris, moving heavy items, light grading and levelling, and site preparation. They need a little bit more room to operate than smaller ones, but they are powerful enough to complete all but the most challenging tasks at these construction sites.

Applicationsfor Large Frame Loaders

Despite being more powerful and capable of using the whole range of attachments than their smaller counterparts, large frame skid steers nevertheless offer quick movement and a low profile so they can move around construction sites without heavier equipment getting in their way. These models perform well for sizable excavation projects, drilling activities, major demolition projects, and grading operations. With the aid of accessories, large frame skid steers can complete almost any task you would encounter on a construction or demolition site, including moving and dumping huge amounts of material.

Clearing Piles Of Snow

A skid steer's bucket may quickly clear snow from a job site or road, but in colder climates, operators may choose to use a snow blade or snow blower attachment.

Excavation

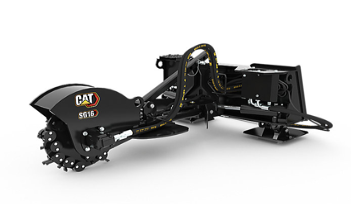

Due to the possibility of adding attachments like a ripper, trencher, tiller, or wheel saw, a skid steer may undertake excavation operations.

Construction

A cement mixer or a pavement miller can be attached to a skid steer to help speed up work on construction and building projects.

Landscaping Works

The stump grinder, wood chipper, tree spade, and trench-digging attachments on a skid steer make it an excellent choice for landscaping work, whereas pallet forks and bale spears are more suited for farm and warehouse operations.

Trenching and Digging

Among the typical digging equipment that skid steers offer are the trench-digger, backhoe, and auger (which operates like a corkscrew to dig a precise hole).

With the right attachment, your skid steer is the best choice for any task on almost any construction site. The safety and maintenance requirements for the skid steer and the accessories that are used on each project must therefore be communicated to skid steer operators by teams.

Different Types Of Skid Steer Loaders

Wheeled and tracked skid steer loaders are the two primary varieties. You can learn more about these various sorts of loaders, including their sizes and capacities, in the articles that are listed below.

Wheeled Skid Steer Loaders

Skid steers were exclusively available as wheeled variants before track steers were created to alleviate some of their shortcomings. Each of them has advantages and disadvantages.

Benefits

Wheeled skid steers work well on flat surfaces like concrete, asphalt, or tightly packed soil. Since they move across these surfaces far more quickly than tracked skid steers can, they can cover more ground more quickly.

Wheeled skid steers are frequently preferable on landscaped grounds where tracked skid steers can rip up surfaces.

They are less expensive to buy and maintain compared to track steers.

Disadvantages

A wheeled skid steer can become stuck in mud since it only has four points of contact (its tyres) to support its weight. If the surface is harsh, a tyre could blow out.

The lifespan of tyres is shorter than that of tracks.

Tracked Skid Steer Loaders

Tracked skid steers have two wide tracks that allow them to carry more weight. Skid steer tracks have the following advantages and disadvantages over tyres:

Advantages

Due to its broader weight distribution and lower weight transfer to the ground, they perform best on wet, muddy, snowy, and loose sand and gravel surfaces. Skid steers with tracks float over soft ground as opposed to sinking into it.

Their increased ground contact and lower centre of gravity enhance stability on slopes.

Tracked skid steers offer a smoother ride than wheeled skid steers. They not only don't compact the ground, but they also provide more lifting force and breakout on soft grounds.

Disadvantages

Before using a track steer on asphalt or concrete, you should stop. Because of how aggressive the track is, Hill said, "It may rip up that type of surface."

Remember that tracked skid steers need more maintenance and cleaning than wheeled skid steers when determining whether to buy a skid steer rather than rent one. They are additionally more pricey.

Track replacement is more labor-intensive than tyre replacement.

Skid Steer Loader Sizes

Classification

Skid steer loaders can be categorised into three classes based on how well they operate:

Small frame: 50 horsepower and less than 1,750 pounds

Medium frame, weighing between 1,750 and 2,200 lbs., with 50 to 70 horsepower.

2,200 pounds and more than 70 horsepower; substantial frame

To select the most appropriate model for you, you must be aware of the capacity requirements for both your workload and your workspace. While larger, more powerful machines could be required in incomplete or uneven work areas, smaller machines are easier to manoeuvre in constrained places.

If you have a large project, you'll need a good skid steer with lots of power. Faster machinery could be more advantageous for a long journey to discharge material. You'll obviously want to be sure your loader can handle the size of attachments you desire in order to avoid overtaxing it.

Guide To Skid Steer Loader Attachments

You may have be aware that a skid steer, sometimes referred to as a skid steer loader, is a device with almost limitless uses. The compact, rigid-framed, engine-powered workhorse is appropriately titled because to its steering system. The wheels merely slow down on either side to produce a "slide," which is more like the machine dragging its feet to help rotate, rather than changing direction to steer. Given that Bobcat is the most well-known manufacturer, you may have heard these called Bobcats.

You may browse through many of the skid steer attachments available for a skid steer loader on our skid steer attachments page, which enables you to use the same equipment to carry out a range of activities. This contributes to their high value. But there is still a lot to learn about these attachments.

What Is A Skid Steer Loader Attachment?

The most popular excavator attachment is a bucket. They are perfect for scooping and excavating because to their steel construction and teeth-like edges. The most typical buckets are those used for ditching and grading stones (sometimes referred to as "ditching buckets") (the trenching bucket). It's vital to consider the quality of the soil and any prospective attachments, like couplers, when choosing the sort of bucket to buy or rent.

Is It Possible To Attach A Skid Steer Loader To Any Skid Steer Loader?

The bulk of the accessories you require can be mounted on your skid steer, even though not all skid steer attachments are compatible. This is because there are several kinds of skid steer, and each one has a varied capacity and set of capabilities. As a result, some attachments can be too much for your specific skid steer to handle. You should get in touch with the makers of each component to find out whether your skid steer and its attachments will work together.

Since the attachment platform was designed to be "universal," and there are adaptors to emphasise this, the majority of skid steers can mount the majority of attachments, but this does not guarantee that they will work together. If you use an attachment with a skid steer that isn't compatible, it could lead to decreased productivity or a dangerous working environment. As we discuss in more detail below, you should also consider if your attachments require low flow or high flow capacity.

Coupling An Attachment To A Skid Steer Loader

Skid steer attachment coupling is obviously a critical stage in the process, but due to the "universal" platform that skid steers operate on, coupling is frequently straightforward and uniform for the majority of attachments. Refer to the following for rapid skid steer attachment coupling:

Taking off any existing attachment

For Hydro-mechanical

Release any system pressure that has been accumulated in the auxiliary lines for machines that have "connect under pressure" coupling. To finish, push the coupler in the machine's direction and hold it there for five seconds. Consult your attachment's owner's handbook to learn if this is required.

Couple the lines after removing them from the hose guide. Simply explained, this lowers the possibility of contamination and reduces pressure buildup for the subsequent use. Follow the instructions described below to unhook the attachment itself.

Uncoupling The Attachment

With motorised coupling machines, the connection pins can be released automatically by pressing a button in the cab, or manually by releasing a lever behind the attachment.

You should progressively back the connection assembly back until its top is clear of the angled work plate.

You can now securely and correctly detach the attachment you don't need before coupling the attachment you do need by following the procedures below:

Coupling The Attachment

While moving gently in the attachment's direction, nudge the work plate slightly forward to line it up with the coupling assembly's angle.

The coupler should be raised and tipped rearward toward the skid steer.

In order to point the coupler toward the skid steer, it should be lifted.

You can check to make sure the coupling assembly is secure by fully lowering the attachment and dragging it along the ground rearward.

Before raising the tool once more, carefully inspect it for any movement and make sure the pins are still engaged. Check the owner's manual for your attachment to see if there are any special instructions for attaching.

If you have a hydro-mechanical attachment, you must connect the hydraulic power after completing the previous stages. The hydraulic lines from the attachments are connected to the auxiliary connectors on the machine as seen above.

Start by securely leaving the machine while maintaining three points of contact.

Cleaning the connector and running the normal flow lines through the hose guide on the left lift arm are the next steps. Always refer to your owner's handbook to determine the proper routing for your attachment.

If your machine has "connect under pressure" connections, you can finally link the hydraulic lines to it by first letting the pressure out. Push the coupler on the machine's coupler and the connection on the work tool together and hold for five seconds to accomplish this.

What Skid Steer Attachments Are Available

This useful, multipurpose gadget is likely already installed on a lot of skid steer loaders. The best part is that some of them will have a special "four-in-one" design with an opening bucket that can be used to dig, push loose debris, and transfer items that have been dragged back (with the bucket open).

Skid Steer Loader Breaker

Similar to a jackhammer, the breaker attachment is a more specialised equipment that is often used for tearing materials apart. This hydraulic "hammer" has uses in construction, demolition, and road upkeep.

Skid Steer Loader Fork

Your skid steer can be effectively used as a makeshift forklift to move huge quantities of cargo on pallets with the help of the fork attachment (most commonly).

Skid Steer Loader Grapple Bucket

The tines on this attachment, which is utilised in many industries, make it simpler to handle heavier and more challenging objects like logs. The bucket of this attachment is used for scooping and holding material (like a freestanding bucket).

Skid Steer Loader Planer

When cutting and milling concrete, the planer often chips away at the material beneath it and can even immediately recycle it.

Skid Steer Loader Spreader

A spreader is an attachment that spreads granular materials like salt, sand, fertiliser, and seed, as its name suggests. In the winter, these are typically used to sprinkle salt to help with snow removal.

Skid Steer Loader Auger

An auger is a helpful accessory for a skid steer for boring large holes in the ground, whether they are required for planting trees or poles, etc. They are hydraulic and come in a variety of widths to suit your requirements.

Skid Steer Loader Steel Tracks

Steel tracks are ideal for improving the handling and traction of your skid steer across unlevel ground, such as sand, stones, and mud. Please be aware that these only work with specific kinds of tyres, including the factory-installed ones that came with your skid steer.

Log Grinder

A log grinder is often employed at a 90-degree angle from the skid steer operator to remove tree stumps and logs for resizing.

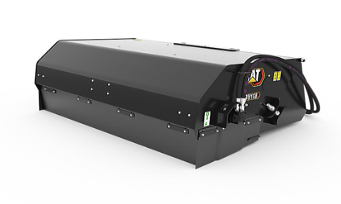

Sweeper

A sweeper is undoubtedly the attachment that is most effective for cleaning, sweeping, and collecting debris both forward and backward. A gutter brush is typically accessible as an alternative for more versatility and effectiveness.

Flail cutter

The ideal attachment for cutting down small trees and light undergrowth is a flail cutter. Due to their floating linkage, which makes it simple for them to follow the ground, they are great for efficiently removing undesirable vegetation, even in confined locations.

Bobcat Skid Steer Loader Range

Triggers Digger Hire Berkshire Copyright© 2022 All Rights Reserved